1965 Malibu Restoration

September 1, 2007

The summer after my freshman year of high school, I was only 6 months away from getting my driver's license. My dad has always been a gearhead and enjoys working on cars in his free time. I had taken on his affinity of classic cars and he proposed that I work on a car all summer with him for my first car. We spend about 4-6 hours a day, 5 days a week for the entire summer. I can't thank my dad enough for not only the car, but the experiences along the way.

Picked up the car for $4,000. It is a 1965 Chevrolet Malibu, small block 283. Interior was a wreck. The engine started but wasn't running well.

First, we took the whole car apart. We pulled out the power train, the interior, and all the trim. We sent it out to get sand-blasted to get all the paint off. We also had the automatic transmission rebuilt by a professional because they're incredibly complicated.

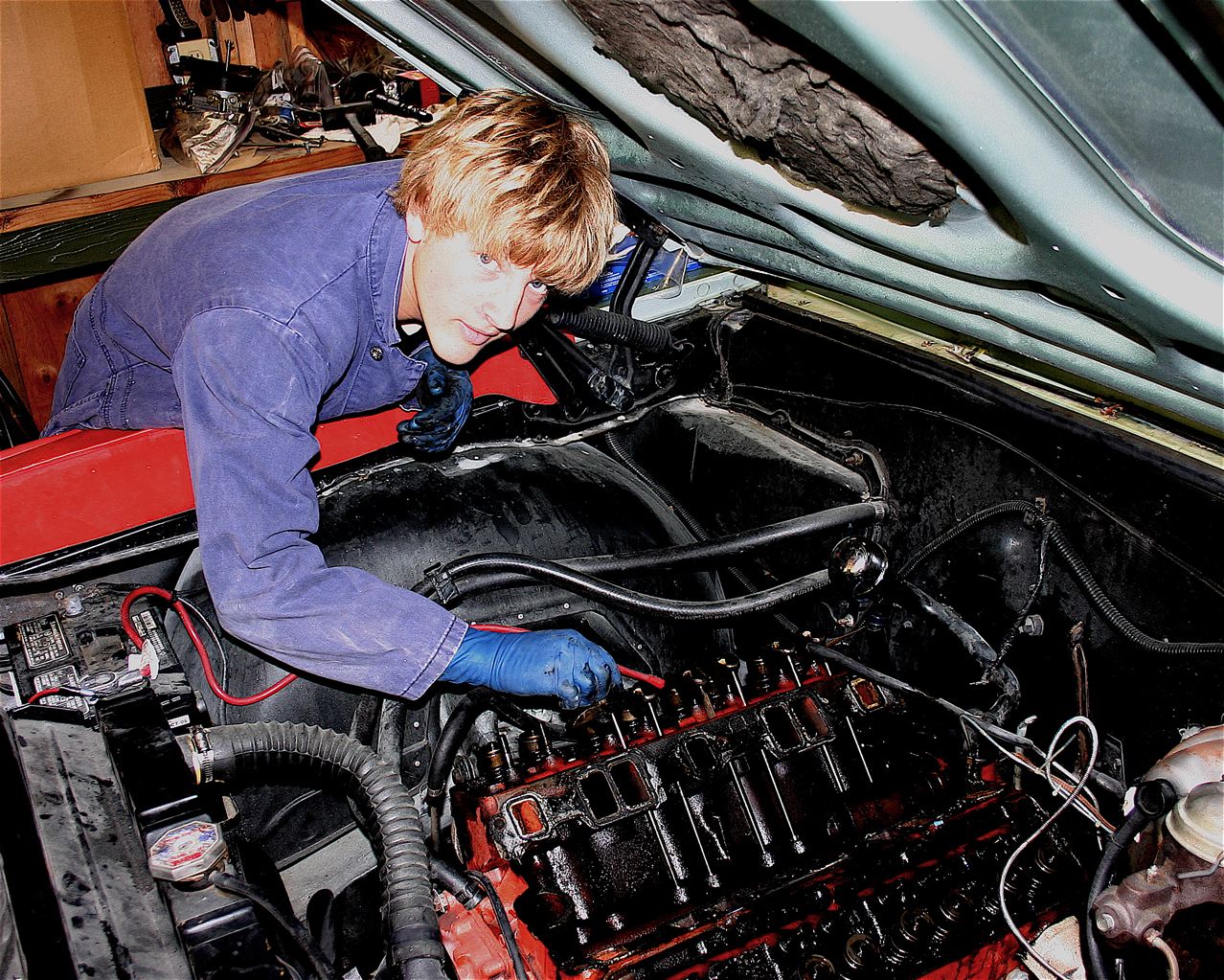

In the meantime, we took the entire motor apart to clean the parts and rebuild it. We bought a few new parts for the engine – an aluminum exhaust manifold, some sexy valve covers, a new alternator and a fresh battery. We refurbished old parts and bolts by soaking them in gasoline to get the grease off, and sandblasting them until they were nice and shiny. With the seats, we replaced all the foam and bought new vinyl upholstery.

When we got the car back, we took of the fenders to make the engine more accessible. On went the spark plugs, distributor, alternator, power brakes, power steering, water pump, fan, carburetor, and exhaust pipe headers.

My dad and I did all the body work and painting ourselves for our first time. We vastly underestimated the amount of time it was going to take. Luckily, this car didn't need much bondo and there wasn't any rust.

We had to wait about 2 weeks before we could start wet sanding the paint. This was an immensely tedious process. We used about 8 different grits making our way up to 2500 grit sand paper followed by buffing and waxing.

On to the interior, we laid speaker wire under the carpet and installed some 6 inch speakers under the back window. We pulled the entire dash out, cleaned it, painted, and rewired some of it. We replaced the door panels but reused most things like door handles and the rear view mirror that cleaned up nicely with some steel wool. We installed seat belts which didn't originally come with the car. Mounted an oil and temperature gauge under the dash along with a stereo system. We got the ignition and doors rekeyed and threw the seats in.

All we had to do now was make sure the motor was tuned to spec, and put all the trim on. While the engine was running, we also noticed a clinking sound on every revolution of the motor. Using a rolled up piece of paper to trace the sound, we deduced that one of the valves was banging against the valve cover. We took the engine apart and sent out the heads to get rebuild. While getting rebuild, they found a flat spot on the cam shaft that was causing the clicking so we had it replaced. We put everything back together and sure enough, the clicking was gone.

And here's the finished product.